MOTIVE POWER HASSLE FREE

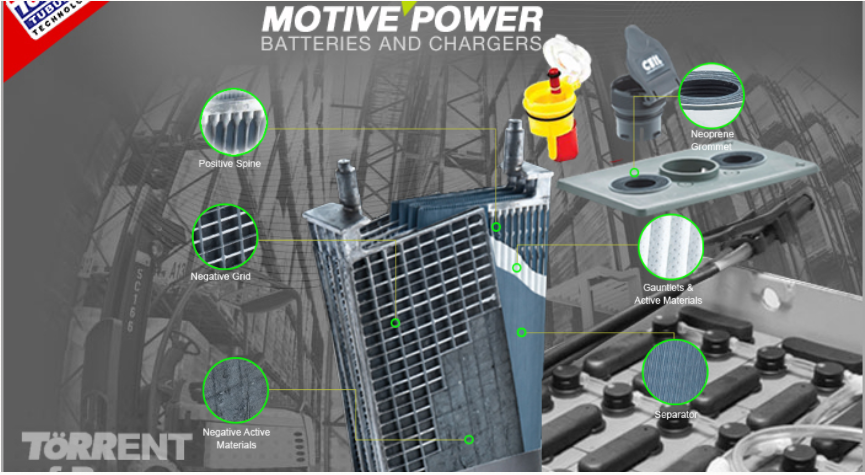

Traction Batteries

CBSEA’s range of Motive Power traction batteries and chargers prevail as a market leader across the globe – servicing OEMs like Crown, Jungheinrich, Nissan & Toyota, renowned 3PLs – DHL, Sankyu, Schenker etc and End-Users across all industries – making CBSEA the preferred choice for traction batteries and chargers.

Keeping in pace with the new demands of traction batteries and faced with the need to power material handling vehicles through longer shifts, our range of traction batteries and chargers provide extra capacity through accessories such as side shifts, clamps and lights, but not at the expense of battery life.

Forklift Operators can prolong the useful life of their forklift batteries by using the CEIL range of traction chargers which will ensure the traction battery is always maintained in peak operating condition. In addition, CBSEA’s large group of well-trained sales and service engineers are always standing by to meet all your needs at the shortest notice. CBSEA has many years’ of experience in the creating the complete concept of battery charging rooms, from initial design and engineering through to complete installation and project management.